The Ultimate Guide to Heavy-Duty Lower Steering Shafts for Off-Road Vehicles

Release time: 2025-09-19

When it comes to off-road vehicles like Jeeps, trucks, and SUVs, having the right components is crucial for maintaining peak performance. One often overlooked yet essential part of an off-road vehicle’s steering system is the heavy-duty lower steering shaft. Designed to endure the intense conditions of off-road driving, these shafts play a critical role in ensuring safe, responsive, and reliable steering, even on the roughest terrains. In this guide, we’ll explore the significance of heavy-duty lower steering shafts, their benefits, materials, and how to choose the right one for your vehicle.

Table of Contents

What are Heavy-Duty Lower Steering Shafts?

A lower steering shaft is a vital part of a vehicle’s steering mechanism, connecting the steering column to the steering gear. The lower shaft helps transmit the driver’s input from the steering wheel to the vehicle’s wheels. Off-road vehicles are subjected to harsh conditions like bumpy roads, rocky paths, and extreme weather, which puts significant strain on the steering system.

A heavy-duty lower steering shaft is specifically designed to handle these demanding conditions. Made with stronger, more durable materials and advanced engineering, it ensures that the steering system can withstand high forces, heavy loads, and constant impacts without failing. This makes it an essential upgrade for any off-road enthusiast looking to maintain control and safety while navigating rugged terrains.

Understanding the Role of Steering Shafts in Off-Road Vehicles

Basic Function of Steering Shafts

The steering shaft’s primary role is to transfer the rotational force generated by the steering wheel to the steering rack or box, which in turn moves the vehicle’s wheels. In an off-road vehicle, the steering shaft also needs to cope with extreme angles, constant vibration, and the heavy demands of off-road driving.

Why Lower Steering Shafts Need to Be Heavy-Duty

Off-road driving puts more stress on the vehicle’s components compared to regular driving. Lower steering shafts in off-road vehicles are subjected to higher forces, as the vehicle needs to make sharper turns and often traverses uneven ground. A standard steering shaft may not be built to withstand these high stresses and could eventually fail, compromising safety and performance.

A heavy-duty lower steering shaft is specifically engineered with these factors in mind. It is made from tougher materials that can resist bending, breaking, and wear, even under the toughest conditions.

Benefits of Heavy-Duty Lower Steering Shafts

Enhanced Durability and Strength

The primary benefit of upgrading to a heavy-duty lower steering shaft is increased durability. Off-road environments are harsh, with sharp rocks, deep mud, and unpredictable surfaces. These conditions place a considerable amount of strain on your vehicle’s steering components. A heavy-duty shaft is designed to handle these stresses, providing you with a long-lasting solution that won’t let you down during critical moments.

Improved Steering Control

When you’re off-roading, precise control of your vehicle is essential for safety and performance. Heavy-duty lower steering shafts help improve steering responsiveness by reducing flex and play in the system. This translates into smoother, more accurate turns, which is crucial when navigating obstacles like rocks, tree roots, and steep inclines.

Longevity and Cost Efficiency

Investing in a heavy-duty lower steering shaft may seem costly upfront, but it can actually save you money in the long run. Because these shafts are built to last longer and require less frequent replacement than standard shafts, they can reduce the cost of repairs and replacements over time. Additionally, the added reliability means fewer breakdowns and interruptions during your off-road adventures.

Safety Considerations

Safety is always a priority, especially when driving off-road. A compromised steering system can lead to dangerous situations, such as loss of control during sharp turns or at high speeds. Heavy-duty lower steering shafts help prevent steering failure, ensuring you have better control of the vehicle at all times.

Materials Used in Heavy-Duty Lower Steering Shafts

The materials used in the construction of heavy-duty lower steering shafts are crucial for their performance. Let’s explore some of the most common materials:

Steel

Steel is the most commonly used material for heavy-duty steering shafts due to its strength and durability. High-quality steel shafts resist bending, twisting, and wear, making them ideal for off-road conditions. Steel shafts can also withstand higher temperatures, ensuring reliable performance even in extreme conditions.

Aluminum

Aluminum is a lighter alternative to steel, often used in performance-oriented off-road vehicles. While not as strong as steel, aluminum shafts offer a good balance of strength, weight reduction, and corrosion resistance. Aluminum shafts are often used in high-performance off-road vehicles where weight reduction is a key concern.

Carbon Fiber

Carbon fiber shafts are becoming more popular for off-road vehicles due to their lightweight properties and impressive strength-to-weight ratio. While expensive, carbon fiber shafts provide superior performance and durability, making them an excellent choice for serious off-road enthusiasts who prioritize weight reduction without sacrificing strength.

Why Material Choice Matters

The choice of material impacts the performance of your lower steering shaft. Steel offers the best strength, while aluminum is favored for its lightweight nature. Carbon fiber, though costly, is perfect for those looking for a high-performance option that combines strength and reduced weight. Depending on your vehicle’s needs and your budget, selecting the right material will ensure that your vehicle performs optimally in the toughest off-road conditions.

Signs You Need to Replace Your Lower Steering Shaft

Like any part of a vehicle, the lower steering shaft will eventually wear out, especially in off-road vehicles that are driven frequently in harsh conditions. Here are some signs that indicate it may be time to replace your steering shaft:

- Loose or Unresponsive Steering: If you notice that your steering feels loose or is not as responsive as usual, it could be a sign that the shaft has been damaged or worn down.

- Vibrations or Noise: Excessive vibrations or unusual noises when steering could indicate that the lower steering shaft is misaligned or damaged.

- Difficulty Turning: A stiff or difficult-to-turn steering wheel is often a sign of a problem with the steering shaft or other steering components.

Choosing the Right Heavy-Duty Lower Steering Shaft

When it comes time to replace your lower steering shaft, there are several factors to consider:

Compatibility

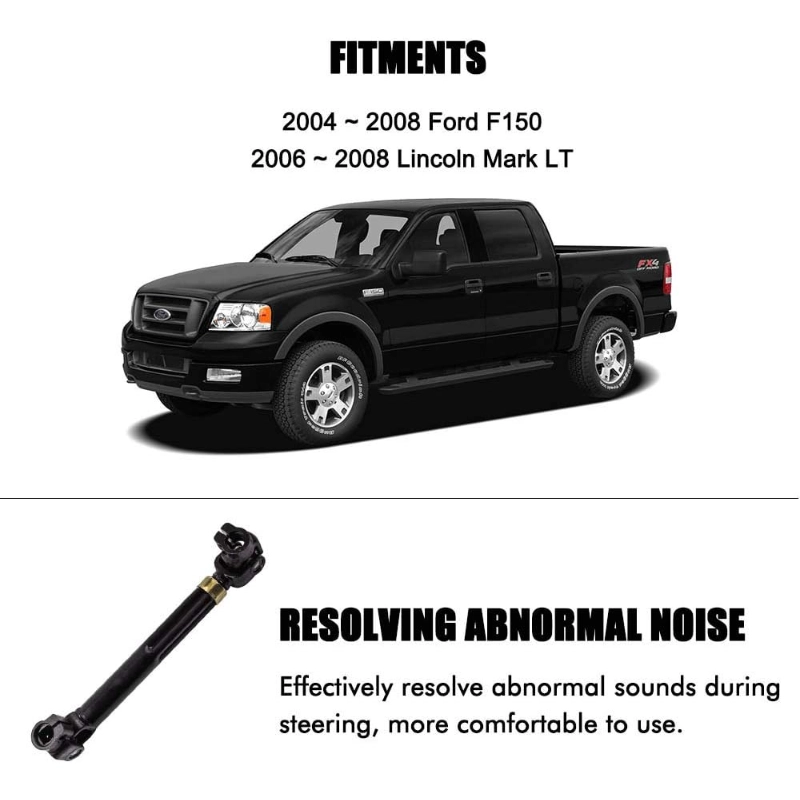

Make sure the heavy-duty lower steering shaft you choose is compatible with your vehicle’s make and model. Off-road vehicles come in a variety of designs, and it’s important to select a shaft that fits correctly to avoid installation issues.

Material and Construction

Consider the materials discussed earlier—steel, aluminum, or carbon fiber—based on your performance needs and budget. Steel is the most common choice for off-road vehicles due to its toughness, but lighter materials like aluminum or carbon fiber may be more suitable for specialized applications.

Brand and Reviews

Choose a reputable brand with positive customer reviews. This ensures you’re getting a high-quality product that will perform well and last longer. Some trusted brands include Spicer, Borgeson, and Moog.

Installation and Maintenance of Heavy-Duty Lower Steering Shafts

Installing a heavy-duty lower steering shaft requires precision and knowledge of your vehicle’s steering system. While it is possible to install the shaft yourself, it’s recommended to have it done by a professional mechanic to ensure proper alignment and functionality.

Maintenance Tips

To extend the lifespan of your heavy-duty lower steering shaft:

- Regularly check for wear and tear.

- Ensure that the steering system is properly lubricated.

- Inspect the shaft for any loose parts or damage after off-road trips.

Conclusion

Heavy-duty lower steering shafts are an essential upgrade for off-road vehicles, providing enhanced durability, improved steering control, and increased safety. Whether you’re tackling rocky trails, muddy paths, or steep inclines, a high-quality heavy-duty lower steering shaft ensures that your vehicle’s steering system can withstand the toughest conditions. By choosing the right material and brand, you can significantly improve your off-road experience while reducing the risk of steering failure.

Ready to upgrade your off-road vehicle? Visit nosen-tech.com for the highest-quality heavy-duty lower steering shafts and expert advice. Free inquiry available!